Foundry

Madras Marine, boasting over four decades of expertise, specializes in crafting large Sand Cast marine propellers, garnering a commendable reputation within the maritime industry. Through unwavering commitment to quality and customer satisfaction, Madras Marine has fostered robust relationships with its customers. The modern and highly mechanized foundry features a melting capacity of approximately 2,000kg and holds approvals from esteemed classification societies such as the IRS and RINA.

This impressive melting capacity for copper-based alloys is facilitated by both electric and oil-fired furnaces, offering flexibility to accommodate growing demands and ensuring uninterrupted production schedules. Innovation is the cornerstone of Madras Marine's operations, exemplified by the development of a pioneering process situated between the melting and pouring stages.

This process effectively minimizes gas inclusion in castings while promoting grain refinement, thereby ensuring the production of high-quality propellers. Madras Marine Foundry primarily deals with three key materials: Manganese Bronze, Nickel Aluminium Bronze, and Gunmetal. These materials are meticulously selected and expertly handled to meet the stringent requirements of marine applications, showcasing Madras Marine's Unwavering commitment to excellence in every aspect of its operations. Furthermore, the incorporation of a sand reclamation unit underscores Madras Marine's dedication to sustainability, with nearly 80% of used sand being recovered and reused. This initiative minimizes waste and environmental impact, further solidifying Madras Marine's position as a responsible industry leader.

More

Design

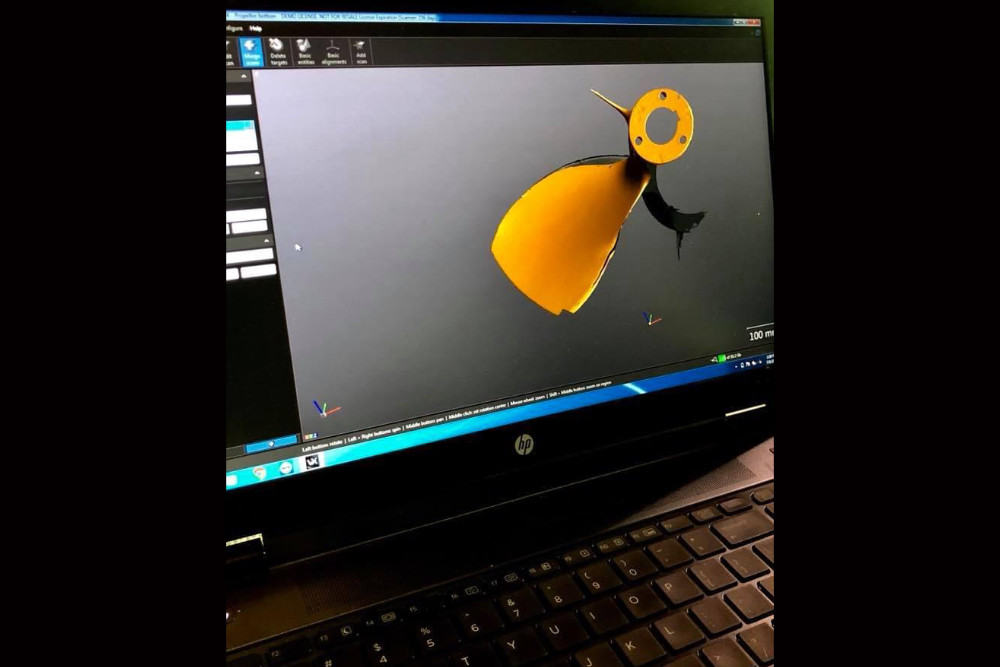

Designing custom-made propeller systems to meet exact requirements

Pattern

Powered with 3D printing technology, the art of propeller pattern making.

Machine Shop

CNC-machined manufacturing facilities achieving precision and accuracy.

Inspection

Regular third party inspections and complete adherence to the industry.

Quality Policy

We follow strict adherence to ISO 90001 standards since 2013.